From the speed of rotation to the choice of blade – we have put together typical setups with which films can be cleanly cut off.

In the last episode of our slitting series, we describedhow to achieve a clean cut edge without fraying, crushing dust, or adhesive residue. Several parameters play a role, from the rotational speed to the immersion speed in the medium, from the lubrication of the blade to the winding tension. This episode is about how to find the right settings for a particular film from these parameters.

The ideal setup for cutting off application tape, adhesive film, transfer film, etc.

For many applications, such as cutting application tape, there is an ideal setup for cutting narrow rolls, tapes and ribbons. If you cut a different material with the same settings, e.g. adhesive film or flock film, this leads to unsatisfactory results.

We have compiled a few typical setups for films that our customers often process for you below.

- Adhesive films with liner

- Linerless adhesive media such as application tape

- Window films

- Flock films

- Flex films

- Foam adhesive films

- Magnetic films

- Laminating films

- Reflective adhesive films

In practice, film dealers in particular will process a mix of materials on one machine. It is not always possible or useful to change the settings in between and especially to change the blade. If different media are to be cut off with the same settings, a compromise must be found.

For example, if you want to cut application tape and self-adhesive films on a NEPATA UA1650 ADWS, you choose a double-edged blade 240 mm x 2.0 mm. This is ideal for application tape, but can also perfectly cut self-adhesive films up to approx. 10 m in length. For slitting adhesive films with larger diameters, however, you should use a blade that is sharpened on one side.

Material test: We help you to find the right settings for your detour

The typical setups for the individual film types are a good starting point and have been tried and tested in our own small film shop, which belongs to the NEPATA Group. In addition, we have carried out many tests for customers, for film manufacturers and film distributors, in recent years.

For fine-tuning, we recommend carrying out additional material tests before starting a larger production. Finally, there are further differences within the individual film types, e.g. in terms of the adhesive, the liner or the general toughness of the material. But the diameter of the roll also plays a role. The time and material for the tests are well invested to avoid rejects or complaints.

You are also welcome to use the NEPATA test studio for material tests. Send us your films, digital print media, papers or non-wovens! We will check all conceivable applications for you and help you find the right settings for your NEPATA slitting machines and conversion centers with cutting unit.. We can even join you via video.

Arrange a test appointment now – just send a short e-mail:

mailto: mail@nepata.de – Subject: NEPATA test studio

Applications and recommended parameters

Adhesive films with liner

-

-

-

-

-

- A blade with single-beveled sharpening that displaces the material to the right

- Medium to high rotation speed

- Medium immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

-

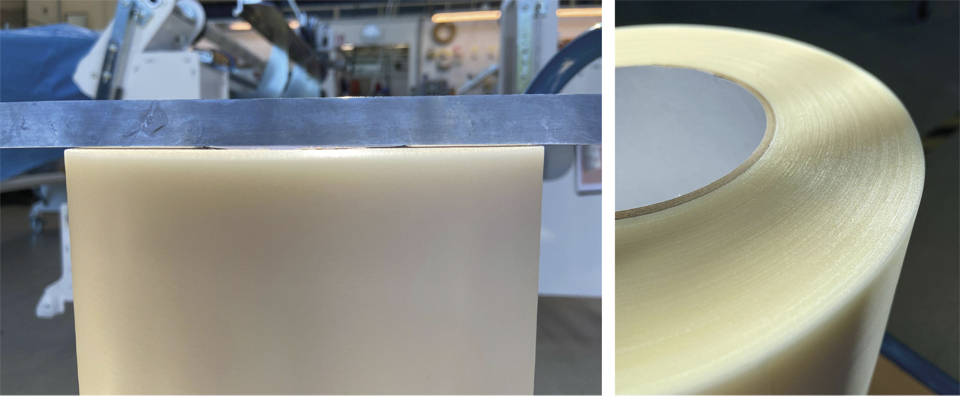

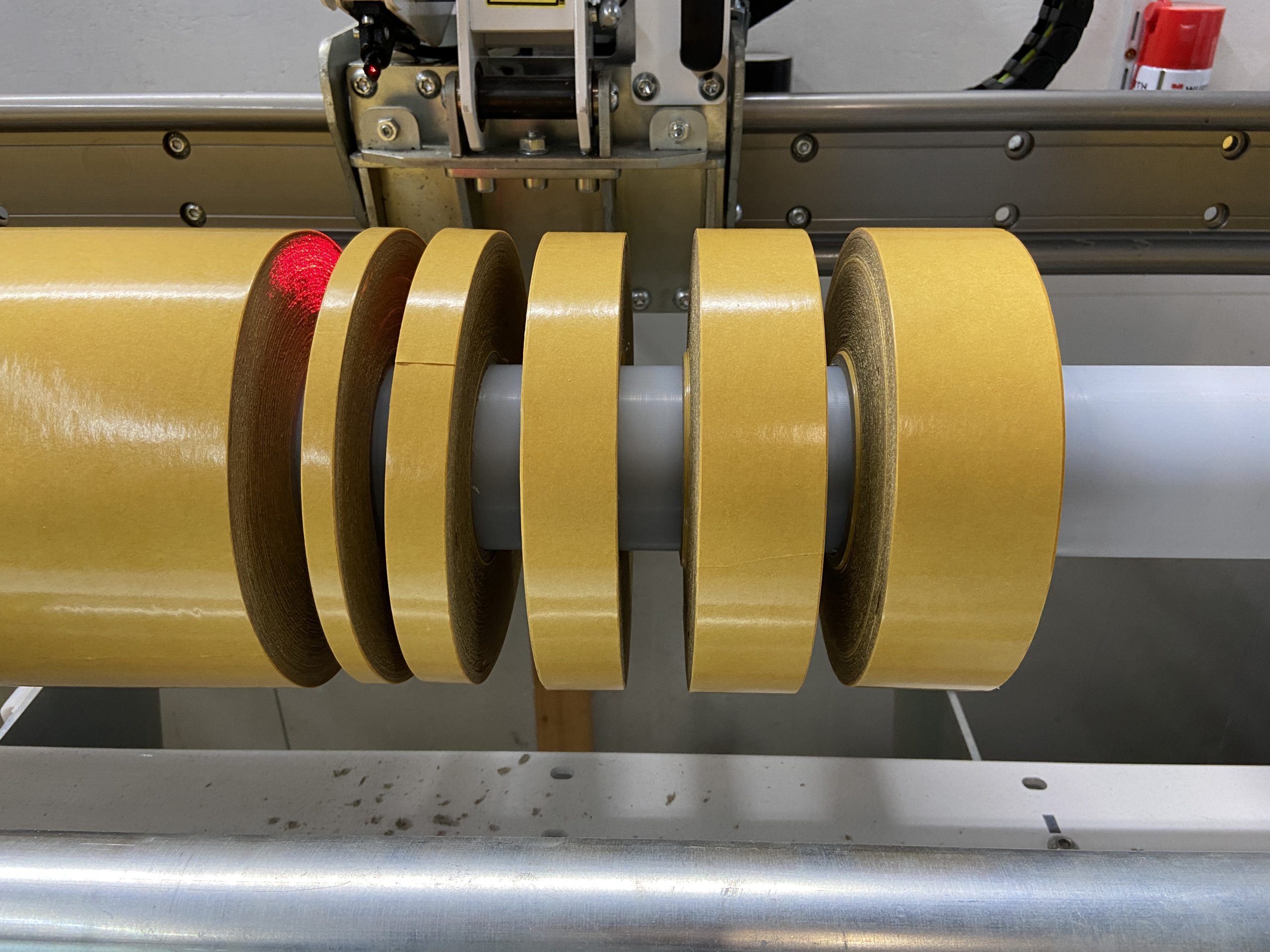

Linerless adhesive media such as application tape

-

-

-

- A thin blade with double-beveled sharpening, which evenly displaces the material

- Depending on the material, an optimum result can also be achieved with a blade with single-beveled sharpening.

- High rotation speed

- Low to medium immersion speed, reduced towards the core

- Rotating blade

- Lubrication system recommended

-

-

Window films

-

-

-

-

- A blade with single-beveled sharpening that displaces the material to the right

- Medium to high rotation speed

- Medium immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

Flock films

-

-

-

-

-

- A thin blade with single-beveled sharpening that displaces the material to the right

- Medium to high rotation speed

- Medium immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

-

Flex films

-

-

-

-

-

- A blade with single-beveled sharpening that displaces the material to the right

- Medium to high rotation speed

- Medium immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

-

Foam adhesive films

-

-

-

-

-

-

- A blade with single-beveled sharpening that displaces the material to the right

- High rotation speed

- High immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

-

-

Magnetic films

-

-

-

-

-

- A thin blade with double-beveled sharpening, which evenly displaces the material

- High rotation speed

- Low to medium immersion speed, reduced towards the core

- Rotating blade

- Lubrication system recommended

-

-

-

-

Laminating films

-

-

-

-

- A blade with single-beveled sharpening that displaces the material to the right

- Medium to high rotation speed

- Medium immersion speed, reduced towards the core

- Rotating blade

- No lubrication needed

-

-

-

Reflective adhesive films

-

-

-

-

-

- A thin blade with single-beveled sharpening that displaces the material to the right

- High rotation speed

- Low immersion speed, reduced towards the core

- Rotating blade

- Lubrication system recommended

-

-

-

-

More know-how about slitting can be found in this video

Previous episodes of our slitting series:

#1 – Which blade for which purpose

#2 – Beware, sharp! The right grinding

#3 – How to avoid fraying, crushing, dust or glue residue?