In many western industrialized nations, there is a shortage of skilled workers everywhere. Also, in film logistics. What to do? Automate, says NEPATA CEO Fabian Franke. By NEPATA CEO Fabian Franke, June 2022

Summary

Many companies already have a shortage of skilled workers – and the trend is likely to continue. Film dealers are also having a hard time finding staff. After all, the work in the roll store and the error-free conversion of film media are demanding and unpopular activities. What could be more obvious than to automate even more? In the following I describe how manual activities and thus the need for (new) workers can be reduced. On the other hand, it is about how to relieve the existing workforce of heavy, tedious or complicated work steps. And lastly, how you can open up new business areas with more automation.

Who still wants to work in the film warehouse?

The film trade is currently facing several challenges for its business model: supply bottlenecks and high freight costs. The persistently high inflation. The skills shortage. The first two problems are hopefully short- to medium-term phenomena. However, the fact that there is more work than personnel is likely to become a permanent condition in many industrialized nations.

For example, the current Skilled Workers Report for Germany is entitled “Skilled Workers Gap at Record Level” and indicates 1.5 million unfilled positions. In the UK, according to British Chambers of Commerce 78% of companies are having problems filling positions after Brexit. And the U.S. Bureau of Labor Statistics shows an unemployment rate of only 3.6% in May 2022 – a very low level for the U.S. (two years ago, after the outbreak of the Corona pandemic, it had been 13.2%).

“Workerlessness instead of joblessness” – I read this catchphrase recently, applicants can choose who they want to work for. An aging population and more academization is a part of the reason why it is becoming increasingly difficult to find employees for crafts and production.

Of course, the lack of qualified or at least motivated personnel also affects the film trade. On my LinkedIn-Timeline I see lots of “We are hiring” updates for service, support or logistics. It is impossible to quantify how large the labor gap is. The industry is too small for concrete figures to exist. But what I can say for sure after my many visits to large and small foil warehouses around the world:

The error-free conversion of film media is – as a classic logistics profession – a demanding but also strenuous activity. This makes them rather unpopular compared to many modern professions.

The fluctuation rate is correspondingly high and some people have reoriented their careers during the Corona crisis.

Work more productively instead of working more

So, are you in the fortunate position that your order books are full? New orders are coming in – but your warehouse crew can barely keep up with assembling the rolls in the desired dimensions? Now there are several possibilities:

1. More staff

But that will – see above – be hard to find, will have to be trained, and may not stick around.

Additional work for existing staff.

But the stress and hectic rush are already high due to low staff capacity, and errors and dissatisfaction continue to increase. Threat of layoffs.

3. More productivity.

Your current employees create more orders.

There are orders, but no personnel. So, you have to do more with less staff.

In order to significantly increase productivity in the film warehouse and in converting, there is no way around more automation. Manual activities must be reduced, time-consuming processes optimized. A practical example: An employee works through delivery note after delivery note, one piece of paper after another. First, he gets the black film and clamps it, cuts it for the first order, removes the master roll and customer roll.

Then the same for the second order, this time with red film. Now delivery note number 3 – and once again black film is called for. If the employee had completed both orders for the black material in one go, he could have saved multiple insertions and removals of the roll.

Relief in the daily warehouse routine

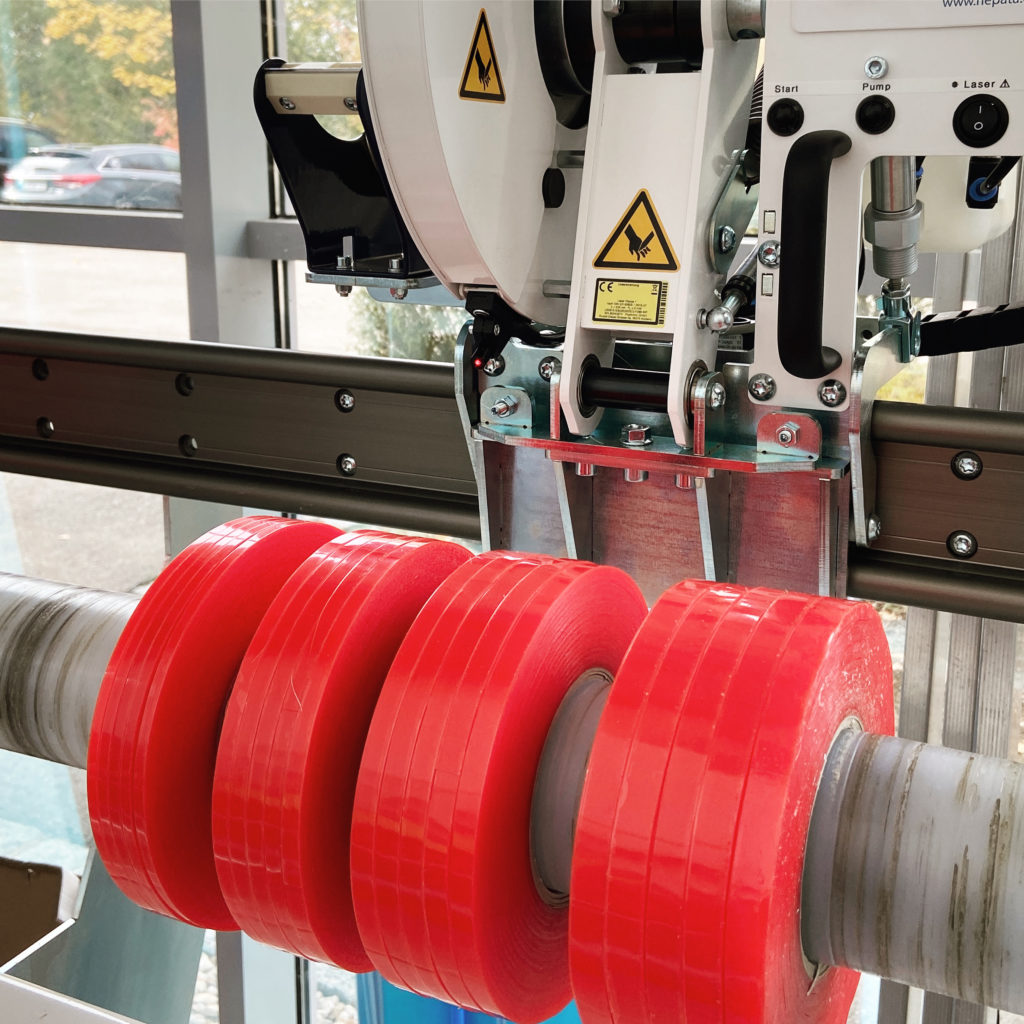

It is precisely in such everyday processes that our solutions come into play. NEPATA develops and manufactures machines for efficient film conversion with a high level of automation. Uniquely, we equip our machines with a self-developed control software. This optimizes the production processes because it establishes the connection between your ERP system or online store, where the orders for film rolls are taken, and the machine, where the ordered dimensions are created from the stock material.

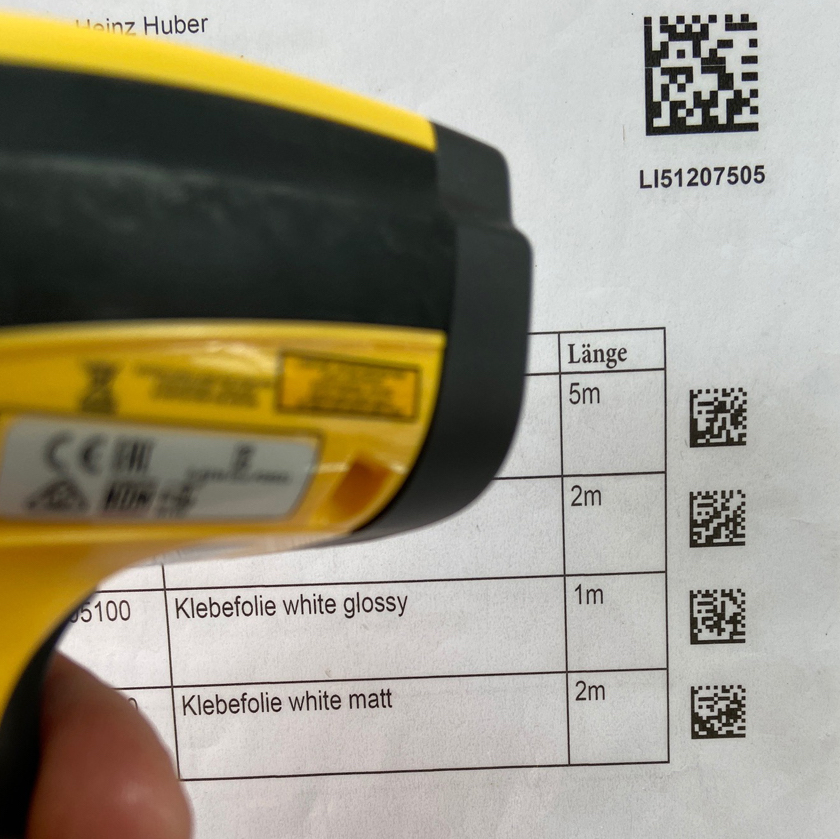

For our example, this means: The delivery notes contain barcodes that include the article number and the target length of the ordered films. The employee can enter these codes on the machine using a scanner. (A fully automatic import of the order data is also possible.) On the one hand, the orders are read in without much potential for error. On the other hand, all orders for the same material can be combined across several delivery notes.

What have our customers achieved in concrete terms?

- Enormous time savings: Over 40% more productivity in wrapping and slitting compared to simple machines and devices.

- Less staff required: 2 instead of 3 people can manage the same number of jobs – and with fewer errors, too, thanks to software support. Personnel are freed up for other tasks or can process more in the same amount of time.

- Rapid ROI: The investment has already paid for itself after only 1 to 2 years through savings in working hours and materials.

Relief from heavy hauling or complicated work steps.

So the numbers speak for themselves. To be clear: I am not telling you to lay off every third employee. The perspective is the other way around: If you actually need more people, but can’t find them on the job market anyway, you have no other option than to increase the productivity of the existing workforce. This also includes creating a good working environment and improving conditions in the warehouse.

The plea for more automation is not meant to be an appeal to fire people from their jobs. It’s a call to unburden people in their workplace.

My great confidence is: If this relief through automation is successful, the job in the film warehouse will also become more attractive again. I see two major areas that professional machines, digitization and robotics can contribute here:

1. Less effort, more ergonomics

Even “tinkered” roll conversion devices are rarely optimized for aspects such as ease of use. With NEPATA rewinders and slitters, on the other hand, a smart design ensures that they are ergonomic, easy and safe to use. To name just two features: The end position of the swivel shaft is adjustable, and the height can be optimally adapted to the height of the operator. An automatic pneumatic coupling ensures vibration-free winding and slitting.

Another aspect is that handling the rolls requires strength (and skill). This fact, on the one hand, limits the number of potential

workers and is also a risk factor for sick leave. This is where I would like to bring our automatic storage systems into play. This makes it possible to automate a strenuous – and not really value-adding – activity, namely picking up and bringing rolls of film to the machine and back again. The rolls are placed in a storage system with vertical robot. The robot provides the rolls that are needed next according to the job queue in the software. The employees can concentrate on executing the orders on the machine.

2. Fewer errors, more satisfaction

People make mistakes, especially when they are under time pressure. The fatal thing in the roll warehouse: There is even more workload because the mistakes have to be ironed out in order to satisfy the customers. Ultimately, this comes at the expense of employee satisfaction.

With software support, on the other hand, you can avoid typical mistakes. That rolls are sent that are too long or too short, wrong colors, matte instead of glossy, etc. Or the classic: Six meters of a ten-meters-roll are unwound for the customer, but the customer is sent the remaining four meters because the employee made a mistake. Our ConvertPlus control software automates the input process on the machine so you can’t make a mistake or forget anything. The central point is that barcode scans are used to match the material with the actual order so that there can be no confusion. All this relieves the employees in logistics, especially when things get busy. You don’t have to concentrate as hard.

Or another example of the automatic storage system. The robot always has an overview of which roll has to be processed next because otherwise it will be overlapped, or which roll is particularly well suited to the current order in terms of run length. These are all things that employees naturally find difficult to deal with, especially under time pressure, and where there is great potential for optimization.

Don’t be afraid of new cutting services and special designs

So if productivity increases noticeably thanks to more automation, your employees will hopefully be happier – and have free capacity free for new tasks. For your business, this is the opportunity for new business areas. Cutting services for third parties are available. Or custom-made products that previously caused too much trouble or were too time-consuming to handle in addition to everyday business. I am thinking here of tapes and ribbons as well as special dimensions.

Film manufacturers, film distributors and film dealers who have already gone down this road confirm again and again:

With automation, converting loses the horror of necessary evil and can become a profit center.

Conclusion: More productivity is a must. This is only possible with automation.

No entrepreneur in the field of film logistics and film trade can turn a blind eye to the fact that productivity has to be increased. Currently, there are not enough workers available and won’t be in the future. It is important to get more done with the existing employees – by relieving them of everything that machines, software and industry 4.0 solutions can do better.

Given the skills shortage (and rising wages), human labor is simply too valuable to be used for exhausting, tedious, or complicated jobs.

In the field of converting, the use of highly automated, software-controlled machines alone makes it possible to achieve an enormous leap in productivity – 40 percent and more. Satisfaction among warehouse workers is also expected to make a jump. After all, this is the only way that film retailers will be able to move into the future: in an interplay of motivated employees and automated processes.

See more strategies for optimizing your film logistics in this video >>>

Would you like to increase the productivity of your converting processes? Arrange a short presentation about automation solutions from NEPATA here.